Unlike buying counterfeit handbags or watches, purchasing counterfeit connectors can be extremely dangerous, to both the people using them and the machines they are connected to. If you don’t know what to look for, you may consider buying a fake connector. Here are the six biggest risks you are taking with your system when purchasing fake designs:

1. Safety is utmost. The most urgent issue with counterfeit connectors is that they place customers at risk, said Brian Krause, vice president, global marketing and communications, Molex Inc. “Over time, counterfeit connectors inter-mated to equipment in the field can lead to degradation of materials and possibly cause shorts or, worst case, thermal incidents.”

Turck adds that not having the correct UL listings is a risk for personal safety, as compromising UL setup in factory automation installations compromises the people working in those situations.

And finally, said Dave Gallagher, product manager at L-Com, substituting materials can lead to potential failure in critical systems.

2. Environmental issues are paramount. Authentic connectors are designed with the environment in mind, ensuring that they will not contaminate or pose hazards to their location of use. For example, said Gallagher, improper materials may not be safe in the intended environment (such as cable burn ratings). If used in a highly flammable environment without the proper burn ratings, a spark could cause a fire. This would not happen with legitimate designs.

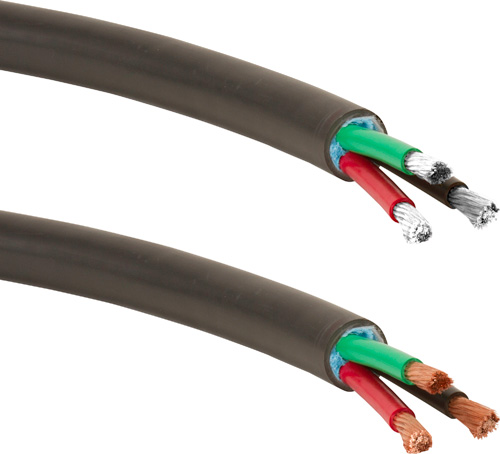

In addition, counterfeit connectors could use materials that are unsafe for the environment or the people that use them. Unless you use verified components, you may not know what is inside them. For example, as pictured, cables could be advertised as copper but are really just aluminum that was colored to look like copper, said Turck.

3. Damage to equipment and more. The use of counterfeit parts can potentially damage equipment, said Molex’s Krause. He added that there is no way to tell how a device or system will perform when it has been inter-mated with counterfeit connectors. They may fail to deliver in terms of performance, insertion/withdrawal forces, or number of mating cycles. For example, said Turck, if a counterfeit component has the wrong gauge size, and has overstated voltage or current ratings, it can cause fires, electrocution, and even fatigue on the connector/cable.

4. Performance slows. Machine functionality is a major problem with counterfeit connectors. For example, said L-Com’s Gallagher. “If your computer transmits at 50% less speed…does it still work? Yes it does…just slower,” he said. So you’re sacrificing performance. Timothy Senkbeil, connector product line manager at Belden added, “Poor connector quality can degrade or interrupt the signal transmissions that are so vital for industrial processes.”

5. Money talks. Clearly, there are huge financial risks with counterfeit connectors. In addition to lost revenue and risks to reputation for legitimate connector manufacturers, trying to troubleshoot and repair a fake connector that only functions intermittently can mean a lot to your bottom line. “Buying a $0.50 cable instead of the $4 cable might sound like a big savings until you find out that cable caused a $5000 truck roll to a remote site,” L-Com’s Gallagher noted.

6. Legal issues may arise. Finally, said Molex’s Krause, “The use of counterfeit parts can result in legal issues related to warranties or service contracts.” And, said Gallagher, if a product does not meet local code rules and the seller knowing sold it with intent, there could be even more legal consequences.

Remember, you should always avoid buying counterfeit connectors in the first place. But if you’re tempted by the low costs presented by what are most likely fakes, read the six dangers above again. It’s not a risk you should be willing to take with your equipment, the people that uses it, or even your company.

Whilst your aims to reduce faking are laudable, you do yourself no great service by faking the photo comparing an aluminium cable with a copper one. The two are clearly the same cable which has been artificially coloured. It would be far more useful (and much less patronising) for us to see a real comparison. You should be ashamed of yourselves.