By Guido Selhorst, Head of Corporate Market Communication, HARTING Technology Group

The electrification of agricultural machinery and auxiliary components is becoming increasingly important. For several years HARTING has focused its innovative efforts on the development of a standardized interface between tractor and attachment. The resulting newly developed AEF high-voltage connections were presented at last November’s AGRITECHNICA trade fair in numerous applications.

The agricultural sector is undergoing transition. It now reflects the industrial sector’s desire for increased efficiency, improved control properties and highly dynamic machinery. The electrification of agricultural machinery and vehicles can make this possible, but the market is significantly different from the automotive sector. A combine harvester is more of a moving and production machine than a simple automobile in traffic. The electrification of tractors, other agricultural machinery and ancillary equipment opens up new perspectives and potential. Tractors that are powered electrically and/or that generate power may, for example, power a seed drill, fertilizer spreader, or rake. The use of electrified agricultural machinery leads to more efficiency and productivity, and on the other hand can reduce the maintenance and error susceptibility of electric motors.

The application of electric drives, e.g. to fans and dosing, increases the efficiency of a seed drill from 60 to 85% compared to hydraulic motors. In addition, the targeted use of operating resources such as seed and fertilizer and the optimized controllability of the attachment significantly reduce power and fuel consumption. The less complex structure also results in a reduction of the installation space required. A second major trend is data generation and data management as a prerequisite for precision farming.

In the field of electrification, the interface between the tractor and the attachment is of critical importance, as different tractor manufacturers must be compatible with different implement manufacturers. To date, the required standard interface for direct and/or alternating current has been missing in action. In addition to a standardized interface for data, the ISOBUS — a reliable and equally standardized interface for the transmission of electrical energy — is required for use under the special conditions and challenges imposed by agriculture. Connectors that have been installed in machines to date are not suitable for the distribution of correspondingly high electrical power within the tractor and on the attachment. This is due to the fact that typical 12-V generators (power approximately 1 kW) cannot cover the energy requirements of a sprayer (1.2 kW), a seeder (3 kW) or a mulcher (140 kW).

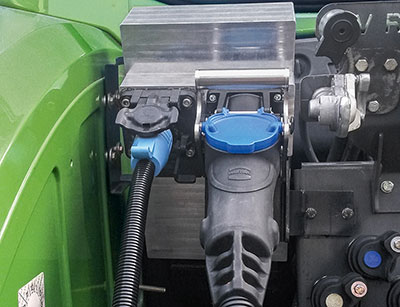

Consequently, the Agricultural Industry Electronics Foundation (AEF) was founded in 2008 as a body for the standardization of various agricultural topics, which HARTING Technology Group joined in 2011. In cooperation with the members of the AEF and all major agricultural machinery manufacturers, the necessary standardized interface was developed — the AEF High Voltage Connector for the transmission of 480 Vac or 700 Vdc between tractor and accessory equipment. AEF High Voltage connection is a new technology designed to meet the future power requirements of auxiliary and attached equipment. In this way, HARTING supports the development of all-electric and hybrid drive systems on the tractor as well as the increasing demand for electric drives on attachments.

The “tracker connector,” HARTING’s first product developed exclusively for agricultural technology, is designed for a maximum output of 150 kW at 480 Vac or 700 Vdc. It features protection class IP69 K in plugged and unplugged state, and is rated for a temperature range of -40° to 85°C. With the ac solution, the “intelligence” remains on the tractor, whereby components on the attachment can be economized. In contrast, the dc variant only needs an interface to supply all electric motors of the attachment. Outside of the standardization, the new interface is also used as a 48 V connection with a maximum power of 10 kW. The solution is also impressive for its breakaway functionality and good feel thanks to rubberised surfaces.

In addition to its robust connector solutions, HARTING offers extensive sensor installations, custom PCB and cabling solutions, and cross-industry IoT solutions that connect machines and equipment to the Cloud for condition monitoring for a wide range of agricultural applications.

HARTING Technology Group

www.harting.com

Leave a Reply

You must be logged in to post a comment.