Learn the proper electrodeposition for contacts and connectors to ensure reliability in your electrical devices.

Contributed by Luke Copp • Sales & Marketing Associate for Advanced Plating Technologies

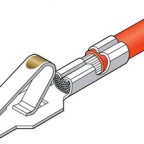

Modern manufacturing relies on critical connections made via strong electroplating, as more and more devices are connected to provide instant access to information and data. However, any electrical device’s effectiveness and reliability depends highly upon the quality of the connections and specifically the plating used on the connector or contacts. Proper electrodeposition is key to ensuring a device performs reliably whereas improper plating can negatively affect performance, utility, and durability of the electrical device.

Gold and silver are two common electroplating processes that produce highly reliable and conductive connections for contacts and connectors. However, they both have their own unique advantages and disadvantages. Both gold and silver are highly conductive and corrosion resistant; however, silver will form a sulfide compound (tarnish) and gold can be a costly option.

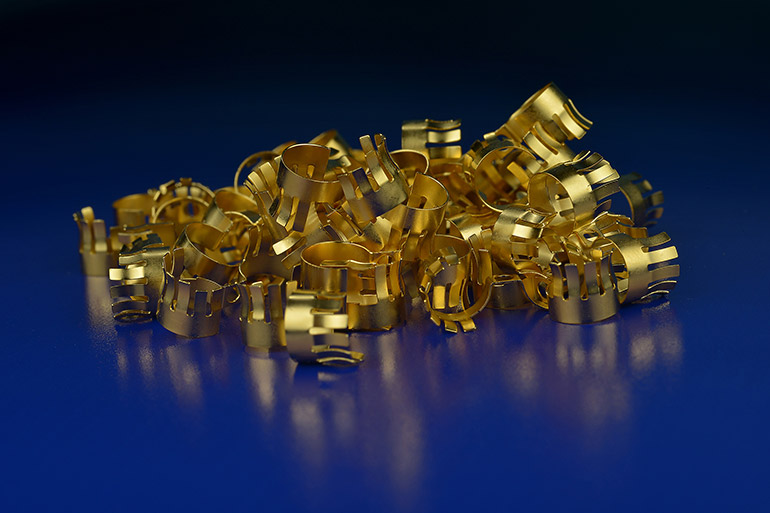

Benefits of gold-plated connectors

Gold is a highly noble (unreactive) metal that can enhance the performance of connectors in a variety of electrical applications. The benefits of using gold-plating include:

• Superior corrosion resistance — In comparison with other metals, gold’s resistance to oxidation or corrosion is extremely high. In situations where the contacts of a connector are likely to be exposed to corrosive substances or conditions, gold plating can serve as an effective barrier from oxidation and corrosion. As a result, gold-plated connectors are an excellent choice for more corrosive applications where the connector or contact may be exposed. Applications include high humidity environments or applications with frequent thermal cycling as well as exposure to corrosive salts or acids. In the latter application, a heavier gold deposit or even duplex gold deposit may be required to ensure there is sufficient gold to eliminate any porosity in the deposit thereby forming an effective barrier to corrosion.

• High electrical conductivity — Besides copper and silver, gold is the third most conductive metal in the world. However, gold does not produce any oxides or other compounds, so it maintains its high conductivity even at elevated temperatures or when exposed to corrosive environments. Its high/consistent conductivity ensures stable current flow even at very low voltages making gold an excellent choice for micro-electronic applications where milli-volts transmit milli-amps.

• Enhanced durability — Electroplated gold can be alloyed with small amounts of nickel or cobalt to increase the hardness from that of pure gold (< 90 Knoop) to as high as 200 Knoop. This hardened gold deposit is commonly referred to as hard gold. When plated to a sufficient thickness (> 50 uin.) over an electrolytic or electroless nickel base, hard gold can provide a durable coating for repeated connection cycles. Hard gold is not prone to fretting or galling due to its natural lubricity.

• Ductility — Because gold is such a malleable metal, it’s suitable for flexible connections and springs. Gold’s ductility makes it more likely that plating will hold up to multiple cycles of contact. However, gold-plated electrical connectors or springs require a suitable underplate material to guarantee the finish meets the design requirements. It is generally recommended that an engineered nickel such as a sulfamate nickel be used as an underplate to gold when plating a flexible contact or spring.

• Solderable deposit — Gold plating is an excellent finish for forming reliable solder joints and will consistently and evenly wet with using just a mild rosin flux without acid activation. Gold can be plated on nearly any substrate including stainless steel terminals or connectors to allow for subsequent joining through soldering. Generally, only a thin deposit of soft gold of 0.00001 in. per side is required to form a reliable solderable gold contact but heavier gold deposits can be soldered as well. When soldering to a gold electrodeposit, the gold plating diffuses into the solder joint through a mechanism called solid-state diffusion. Because of this phenomenon, care should be taken to not exceed more than 3% by weight gold in the solder joint as this can cause embrittlement within the joint itself. As a general rule, deposits of < 0.00005 in. per side will result in less than 3% by weight gold in the solder joint.

• Non-magnetic — As a final point, gold is not magnetic. This is advantageous in scenarios where electromagnetic fields can create interference. For instance, gold plating may be suitable for connectors used in medical equipment like Magnetic Resonance Imaging (MRI) scanners.

Benefits of silver-plated connectors or contacts

Like gold, silver is a precious metal that provides a very conductive surface while forming an effective barrier to corrosion. Its primary advantage is cost — it is about 1/100 the cost of gold which allows for a wider range of use and plating at higher thicknesses than gold. The primary disadvantage of silver is that it is a semi-precious metal and forms sulfur compounds such as silver sulfide or tarnish which can affect the conductivity of the silver electrodeposit over time. Its advantages include:

- Highest electrical and thermal conductivity — Because of its high conductivity and lower cost, silver is perhaps the ideal precious metal for applications where high power transfer of electricity is a design requirement. Examples include plating of current exchange bodies, fuse cutouts, stabs, terminals bus bars or other high-power connectors. Because of the lower cost, plating of larger copper or aluminum conductors with silver is not cost prohibitive and provides a very reliable precious metal coating that resists oxidation and produces low contact resistance. Aside from electricity, silver is also an excellent conductor of heat, which allows connections that transfer large amounts of power to naturally regulate thermal hot spots preventing oxidation of the substrate materials.

- Protection against corrosion — Like gold, silver is a precious metal that can form an effective barrier to corrosion. Because of its lower cost, silver can commonly be plated to thicknesses exceeding 0.001 in. per side forming a very pore-free precious metal barrier to corrosion. Silver is commonly plated over an electrolytic or electroless nickel barrier further increasing the overall corrosion protection. When plated over copper or aluminum conductors, silver forms an effective barrier to prevent the substrate materials from forming compounds or oxides. This eliminates increase in contact resistance or thermal hot spots in a conductor over time.

- Superior lubricity — Silver is a natural metallic lubricant which provides outstanding lubricity even at extreme temperatures. It is an excellent choice for applications such as high temperature threaded or sliding contacts where galling may be a design concern. Silver is commonly used for plating of stainless steel and other high temperature alloys to preventing seizing of moving or threaded parts within turbine engines or turbo chargers where temperatures can exceed 1250°F.

Silver provides outstanding sliding lubricity on high contact pressure switches or contacts including fuse pad or stab connectors or high pressure socket connectors. The use of a lubricous nickel underplate such as electroless nickel can further enhance the lubricity and wear properties of silver electroplating on a connector or contact.

Gold versus silver: what are the differences?

Gold and silver are among the two most frequently used precious metals for connectors and contacts in various sectors. Here are a few major differences between gold and silver electroplating.

- Cost: gold plating disadvantage — Global industrial demand, political and economic uncertainty, and currency devaluation all play a role in driving up the price of gold. Many countries and people turn to gold in periods of economic instability because of its globally accepted value as a currency alternative. However, with the IoT, gold is now sought for more industrial reasons than merely as an investment or as decorative jewelry: gold is truly an essential metal in the production of modern electrical and electronic devices.Increasing gold prices can significantly affect the manufacture of gold-plated components, especially for applications which use heavy gold deposits. Even though no other material can match all the properties of gold, silver has many similar properties at a fraction of the cost. Silver can be plated more heavily and at a lower cost with deposit that yields many similar properties. However, the formation of sulfide compounds or silver tarnish, is one of the limiting factors for silver in applications very sensitive to increases in contact resistance.

- Silver tarnish: silver plating disadvantage — Silver does not form oxides or compounds with oxygen under normal conditions; however, silver plating does form various sulfur compounds such as silver sulfide. Although silver sulfide compounds are relatively conductive, they do increase the contact resistance of the silver plating over that of pure silver alone. In many switching applications, any silver tarnish is effectively wiped from the surface within the sliding contact zone. However, in static applications, silver sulfide or tarnish can increase the contact resistance enough to change the signal path for very low voltage applications. Various anti-tarnish inhibitors such as Enthone’s Evabrite products or Technic’s Tarniban products are available; however, all of these anti-tarnish compounds do add an organic or metallic film on the surface that alters the properties of the silver electrodeposit away from that of pure silver.

In contrast to silver, gold does not form sulfide compounds or tarnish under any normal condition. That makes gold a more viable option for lower voltage signal transmission applications where minor changes in contact resistance can impact product performance. Critical applications such as life-safety sensors or applications for autonomous vehicles require extremely reliable real-time signal transmission that only gold plating can provide.

The bottom line

Selecting the appropriate metal plating for connectors and contacts is a key part of manufacturing a reliable product. The type of electrodeposit used can impact the product’s quality, performance, longevity, and cost. Gold and silver are both high-quality precious metal deposits, but they have different unique benefits and drawbacks that should be considered prior to specifying a specific finish.

This article is condensed from a larger article, which can be found at advancedplatingtech.com/blog/.

Advanced Plating Technologies

advancedplatingtech.com

Leave a Reply

You must be logged in to post a comment.