Winners of the 2021 LEAP Awards (Leadership in Engineering Achievement Program) were announced this afternoon in a digital ceremony, with products across 12 categories. This annual competition saw a record number of submissions, as it aims to celebrates the most innovative and forward-thinking products serving the design engineering space. This year’s winners were chosen by an independent judging panel of 12 engineering and academic professionals.

In addition to three innovative connectivity technologies notching the gold, silver and bronze awards, two honorable mentions were made.

Taking the Gold was Astera Labs, which has successfully executed to deliver the industry first CXL Smart Retimers with 6x lower latency and integrated server fleet management capabilities to realize the vision of AI in the cloud with its Aries Smart Retimer Portfolio for CXL 2.0.

Heterogeneous computing, where GPUs/AI processors and other accelerators work side-by-side with general-purpose CPUs, and workload-optimized platforms are redefining the connectivity backbone in the next generation of servers. This new backbone requires faster and lower-latency interconnects. The deployment of PCIe 4.0 with 16 GT/s, and PCIe 5.0 and CXL with 32 GT/s helps enable this high-speed connectivity backbone but requires a high-speed signal reach extension solution to overcome signal integrity challenges. Retimers, first defined in the PCIe 4.0 specification, compensate for the signal lost by retransmitting a fresh copy of the signal every time, effectively doubling the reach between a root-complex and end-point devices.

The Aries Smart Retimers are designed to empower system designers to easily double the signal reach and achieve plug-and-play interoperation without compromising interconnect topologies even at 32 GT/s speeds of CXL and PCIe 5.0 technology. Astera Labs is the first to deliver working Smart Retimer SoCs for CXL applications with up to 32 bi-directional lanes. The Aries Retimers have been assigned or being considered for 8 new patents for its innovations.

The Aries Smart Retimer Portfolio – Why #1 in the industry?

- • Features an innovative architecture that enables the Retimer platform to learn, automatically adapt, and select optimized adjustments for a robust link-up and plug-and-play interoperation.

- • Delivers 2x lower power, 6x lower latency, and uses 2x fewer components than alternative solutions.

- • Allows data center system designers to future proof their systems, delivering a reach extension solution that can easily and quickly scale from PCIe 4.0 to PCIe 5.0 to CXL architecture.

- • Features a powerful array of Smart Link Health Monitoring capabilities to simplify data center fleet management and improve overall resource optimization through deep system visibility. This results in a system operator being able to detect early signs that a signal is beginning to degrade, quickly identify the exact location/nature of the issue, and work to replace the faulty component before it negatively impacts overall system availability.

- • Designed to support a wide array of system topologies and applications including all PCIe clock modes (SRIS, Common Clock, and SRNS), several bifurcation combinations (1×16, 2×8, 4×4 etc.), and industry specs.

The Aries Smart Retimers are designed to empower system designers to easily double the signal reach and achieve plug-and-play interoperation without compromising interconnect topologies even at 32 GT/s speeds of CXL and PCIe 5.0 technology.

Retimer’s unique position in the middle of a link between two processors, helps it do more than simply amplify high-speed signals over longer distances. Astera Labs recognized the end user’s need for diagnostics and built-in a powerful array of Smart Link Health Monitoring features to simplify data center fleet management and improve overall resource optimization through deep system visibility. Astera Labs provides full-featured C and Python SDKs, enabling rapid, easy-to-use integrations of advanced diagnostics through Aries. This results in a system operator being able to detect early signs that a signal is beginning to degrade, quickly identify the exact location/nature of the issue, and work to replace the faulty component before it negatively impacts overall system availability. Aries C-SDK enables real time monitoring for resource optimization and predictive failure. The diagnostics and constant feedback on resource management allows optimization of customer’s total PCIe bandwidth.

With the Silver Award, is binder USA’s series 670 NCC (Not Connected Closed) Subminiature Connector, which meets the growing demand for reliable circular connectors in applications with both restricted space and high protection requirements. These newly-developed 5-pin subminiature connectors feature a bayonet closure and cable bushing from 3.5 to 5.0 mm. The flange-type socket is offered with soldered and dip-soldered contacts.

Series 670 NCC connectors use binder’s unique spring cover design to completely protect contacts against water, dirt, and penetration by foreign objects, even when disconnected. (Protection to IP67 when mated and IP54 when unmated.)

Highlights:

- Contacts: 5

- Degree of protection: IP67 (mated)/IP54 (unmated)

- Rated current: 2A

- Rated voltage: 50 V

- Designed for > 1,000 mating cycles

- High resistance to vibration and shock loads

- Heat/cold resistant within operating temperature range of -25°C to +85°C

The Series 670 NCC Subminiature Connector is ideal for applications with restricted space and high protection needs (such as watertightness), and where frequent mating/de-mating may be required. These applications include:

- Medical technology

- Test and measurement instrumentation

- Temperature analyzing systems

- Washdown environments

- Indoor/outdoor lighting and signage

The binder Series 670 NCC sets a new benchmark in terms of providing permanent protection, filling a market need, which no competitors have yet effectively entered. The change to the industry is simply expanding the options for engineers, enabling them to make better, more innovative machines.

binder’s Series 670 NCC connector helps design engineers build more reliable, certified protection into their machinery or equipment – without any additional cost for components and assembly. Because the two halves of the NCC connector remain closed when disconnected, the contract area is always protected against water, dust, and foreign particles. This provides engineers with a versatile, rugged connector solution for even the harshest environments.

The binder 670 NCC subminiature connector evolved from the NCC 770 series. The 670 NCC connector is smaller than the 770 series, and offers greater (permanent) protection, in spite of requiring less space.

binder’s 670 NCC offers the advantage of a compact connector that delivers reliable performance under harsh environmental conditions. If an application requires frequent mating/de-mating, the 670 NCC offers IP54-level protection even when disconnected (and IP67 when connected). Additionally, the 670 NCC offers very high durability (>1,000 mating cycles).

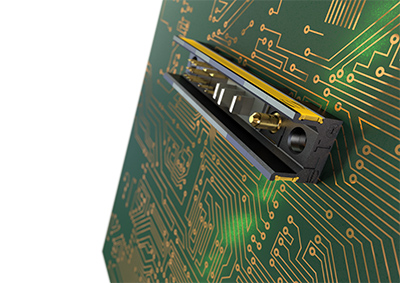

In third place at the Bronze level was Harting, recognized for its Individual PCB connexion in a modular design. With the har-modular interface, connector maker HARTING offers a completely new approach for individual board-to-board connection. Despite offering one of the most comprehensive DIN 41612 portfolios on the market, the company kept on getting customer requests that could not be met with serial parts at all or in a meaningful manner. More individuality was needed. This challenge was tackled at HARTING in Espelkamp by creating a modular system of individual building blocks for the industrial lifelines. They transmit data, signals or power and can be combined in any chosen sequence. Or as HARTING likes to say: CREATE YOUR OWN!

The DIN 41612 multipole connector is one of the best known solutions for connecting PCBs and rack systems in appliance engineering. It is available in many different versions, depending on the services or signals requiring transmission. The HARTING company from East Westphalia Germany has kept on adding to its DIN 41612 portfolio for several decades, also expanding it in line with customer demands. But times change, and here particularly the appliances’ development cycles, along with the flexibility required from the connection technology. Especially as, despite a great variance of standard solutions, HARTING was recently approached by more and more customers with requests that could not be fulfilled with standard solutions at all, or only inadequately. There was either no matching solution, or the chosen solution only uses some selected contacts of a standard solution. This left contacts unused, wasting space in the appliance. In the development of new appliances, one had to wade through the large range of possible connection technologies and might still not arrive at a satisfactory solution if one was unlucky.

HARTING accepted this challenge, wanting to provide appliance developers with better support, and to ease their way to the finished appliance with a modular system. The solution is called har-modular. A modular design of freely combinable connector modules for all lifelines of industrial appliances. Irrespective of whether they need to transmit power, signals or data, the developers can combine the required modules online in a configurator and order them from batch size 1. The variance of the modules and their greatest possible number per connector thus lead to over a trillion potential combinations.

All har-modular are structured by the same principle. In a first step, users select the type of media to be transmitted, and how many contacts are needed in each case. This is what the number and selection of modules will be based on. The second step requires the selection of two guide elements ensuring reliable guidance and contacting in the plug-in process. They can be made from metal or plastic. The position of the guide pins is freely selectable, but they should be at either end of the assembled multipole connector in an optimal case.

In the third and last step, all the elements are interconnected by means of two guide bars. These are locked in on both sides one after the other to finish the individual connection. As is familiar from the DIN range, these individual solutions can be assembled for mother-daughter card arrangements as well as mezzanine connections.

Special Honorable Mentions were given to LittelFuse and Molex.

The Littelfuse SPXI in-line solar fuse is specifically designed for the protection of photovoltaic (PV) systems. These 1500 V dc fuses protect PV systems from overloads and short circuits to minimize damage to solar panels. The compact case size offers design flexibility when space is at a premium. It integrates into an in-line assembly within a wire harness and can be electrically insulated by either overmolding or using heat-shrink. The product label features a QR code, offering access to part numbers, volts, SAP variables, programming terms, and date codes in real time for easy access. Littelfuse offers multiple ampere ratings to match specific requirements in a variety of applications.

Mirror Mezz connectors from Molex offer maximum design flexibility by allowing users to pair different connector-height versions to achieve the desired stack height for an application. Mirror Mezz’s height configurations of 2.50 and 5.50 mm, respectively, can self- or cross-mate to achieve a total stack height of 5mm, 8mm or 11mm. Being a mirrored interface and housing makes possible saving significant capital on components and assembly while permitting expanding stack heights exponentially by mixing and matching different connectors.

Stitched contact structure reduces lead-times, and the connector design allows for a simplified product matrix. The intricately designed terminal structure provides numerous mechanical strengths while also benefiting from cutting-edge electrical features for some of the faster speeds in the industry.

Leave a Reply

You must be logged in to post a comment.