Some connector applications put a high priority on very low mating forces. Examples include:

- Connectors with very high numbers of conductors

- Insufficient room in a system for injector/ejector hardware

- Awkward position inside the box that does not permit the operator to apply a lot of force

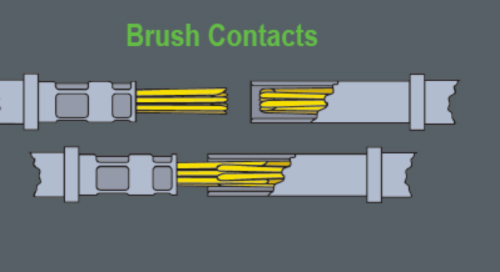

Bendix Connector Corp., now absorbed into the Amphenol Military-Aerospace connector division, makes a family of connectors with mating forces as low as 1-1.5 oz per contact. In order to achieve a high reliability interconnect in this environment, these connectors use a very clever unique bristle brush contact design. The contact interface is composed of multiple wires bundled at the base a bit like a paintbrush. The mating connector also has bundled wires. The ends of the wire are pointed so that as they are pushed together during mating, the wires slip past each other, creating a mating interface with many redundant mating surfaces. This mating interface is quite tolerant to the shock and vibration found in military applications as well as surviving many thousands of mating cycles.

The brush bundle fits inside tubes that align individual contacts during mating. These concentric tubes provide an additional level of protection from adverse chemical or corrosive environments. These contacts can be attached to individual wires with crimp barrels, or solder cups. These contacts can then be snapped into cavities in a multitude of housing configurations to create a family of board-to-board or board-to-cable interconnects.

This venerable connector family has earned it stripes in military service with more than 25 years in the field, and over 1 billion brush contacts sold. Applications include the M1A2 Abrams tank, F-16 Falcon and F/A-22 Raptor Jet fighters. More recently, Lockheed Martin uses the Bristle Brush contacts to give the F-35 Lightning II joint fighter its advanced capabilities and flexibility to serve multiple branches of service with state-of-the-art performance. The British/German consortium designed the Bristle Brush into a sophisticated air-to-air heat-seeking missile, the AIM-132 ASRAAM.

All of these applications benefit from the connector’s ability to handle intense vibration and g forces up to 50 g without any reduction in electrical performance.

Connectors in military applications like these have unique requirements beyond the ability to perform in adverse environments. Suppliers must agree to supply these connectors for the life of a production program and beyond for repair parts to support units in the field. Many of these military programs last for decades. The electronics can be upgraded over time, but often the basic systems need to be backward mateable to the wiring harness from the first production systems. The very long life of these military connector systems enables connector companies to justify tooling very special connectors, even for low volume applications.

The Bristle Brush is one of those very clever ideas that have endured onslaughts from competitive connectors offering more density, lower cost and higher speeds. It survives because it works.

Dear Sirs

I use to change whole modules due this connector fail due thousands of connection and disconnections procedures. I need to replace just the connector and need a catalogue to identify the ones I have here. It has not any number

Do you can guide me about please?

Jose