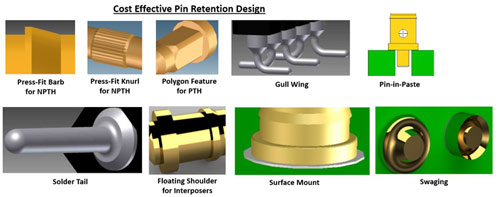

When selecting components for their applications, mechanical and electrical engineers, must understand some general guidelines for their PCB interconnect requirements. Below is a short list of nine of the most common and cost-effective pin retention designs and where they may be used.

When selecting components for their applications, mechanical and electrical engineers, must understand some general guidelines for their PCB interconnect requirements. Below is a short list of nine of the most common and cost-effective pin retention designs and where they may be used.

- Press-Fit Barb — is specifically for non-plated through holes. This is the easiest and most cost effective retention feature to machine. Like a fishhook, when the barb is set into a thermoplastic or FR-4 epoxy insulator, the pin will not walk out.

- Press-Fit Knurl — is a gear shaped feature, intended for non-plated through holes. This is specifically for any application that requires anti-rotation, such as a long right-angle pin or a wire-wrap pin. As a result, you do not want either to spin in place when pushed or torqued.

- Press-Fit Polygon — is a technique of designing a low profile pin with a multi-facet barrel such that, when it is press-fit into a multi-layer PCB, only the points of the polygon achieve a gas-tight mechanical and electrical connection with the copper wall. This technique is used for hard-to-solder thick PCBs.

- Gull Wing — is a method to achieve stronger solder joints by increasing the PCB land surface area versus a SMT component that has in-line circular pads. Since the gull-wing leads are bent outward, it makes solder joint inspection and access much easier.

- Pin-in-Paste — is an ideal technique for mechanically strengthening connector components mounted on SMT PCBs. The lead is specifically designed not to protrude beneath the PCB, and the pin shoulder is reflowed on the top PCB pad.

- Solder Tail — If the engineer can live with the above board height, pins and sockets with solder tails are beneficial because they require a minimum diameter plated through hole inside the PCB. This allows for more signal routing channels between pins, which effectively minimizes the required amount of PCB layers, which in turn saves on cost.

- Floating Shoulder — is a technique that designs a feature onto the pin body, allowing it to float in a vertical direction. This is ideal for applications involving uneven surfaces or SMT assembly over a very large area, where coplanarity is a concern. A surface mount socket assembled with floating pins can compensate for peaks and valleys caused by warp, twist or uneven solder paste.

- Surface Mount — The benefit of SMT attachment is it allows the designer to optimize both sides of his PCB for component attachment. It also offers the benefit of double density packaging.

- Swaging — is act of riveting or mechanically fastening a pin into a hole. A very old and reliable technology, it is ideal for engineers may want to solder heavy gauge wires to a PCB. The benefit of swaging is the swage pin is not solely relying on a solder joint, but rather the mechanical fastening. This prevents the pin from reflowing and falling out of the hole during soldering of heavy gauge wires.

Martin Houlroyd is Principal Engineer/Marketing Specialist at Preci-Dip. He has worked in the interconnect industry for 35 years. Email him at m.houlroyd@precidip.com.

Leave a Reply

You must be logged in to post a comment.