Needle flame and glow wire testing are two approaches to determining the flame-retardant performance of materials like various plastics and the electronic devices that incorporate those materials. Needle flame tests are defined in IEC 60695-2-2, while glow wire testing is defined in IEC 60335 and IEC 60695. UL94 is another material burning test and can be either a horizontal burn (UL94 HB) or a vertical burn (UL94 V) test. This FAQ looks at glow wire testing, needle flame, and UL94 burning to test and compares the performance and testing requirements for the various approaches.

These tests are designed to protect against fault conditions like excessive leakage currents, poor (high resistance) electrical connections, or outright short circuits that can cause overheating resulting in fire. Since connectors can be subject to all these fault conditions, they are among the components most often required to pass these tests. The glow wire and needle flame tests are sometimes used in combination. The glow wire test is administered first, and if the part fails, the extent of the burning hazard can be further assessed with the needle flame test.

Glow wire testing

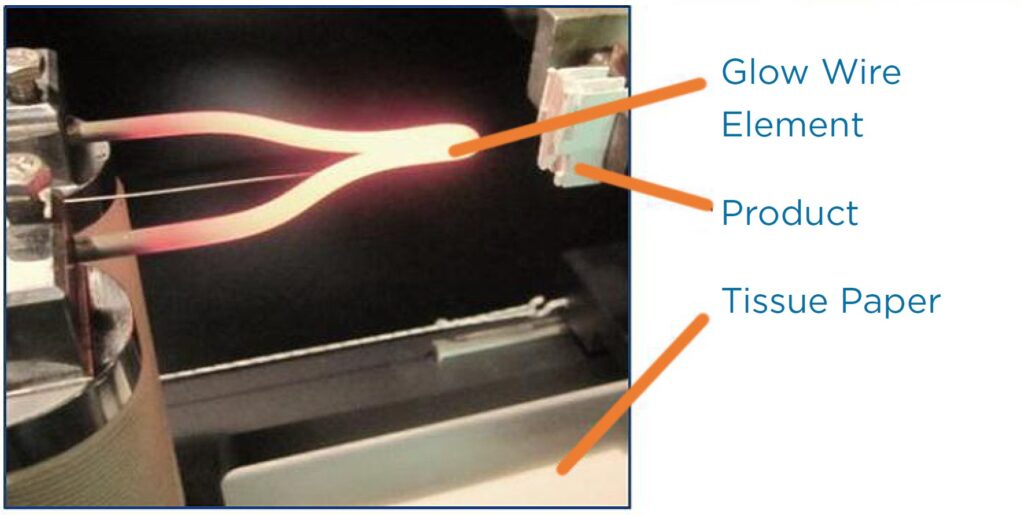

Glow wire testing uses a heating element at a pre-determined temperature, depending on the specific test. The heating element is called the ‘glow wire.’ In addition, a fiber cloth called tissue paper is below the material or device being tested. After reaching the required temperature, the glow wire is pressed against the test specimen using a force of 1 N for 30 seconds (Figure 1). If the specimen catches fire, the ignition start time, duration, flame height, and, if the material drips, notes regarding if the fibers of the tissue paper are charred or ignited are recorded. The test is repeated three times using new specimens, changing the mounting orientation so each unique surface, like front or back, top or bottom, and left or right side, is tested. Test samples for glow wire testing should be at least 60 mm long and at least 60 mm wide with a thickness of 0.75 ±0.1 mm, 1.5 ±0.1 mm, or 3.0 ±0.2 mm.

Glow wire testing complies with IEC 60335-1 for household and similar electrical appliances for resistance to heat and fire and includes a glow wire ignition temperature (GWIT) of at least 775 C° as defined in IEC 60695-2-13 and a glow wire flammability index (GWFI) above 850 C° defined in IEC 60695-2-12. Glow wire performance requirements are defined in IEC 60335. Glow wire testing can be performed on raw materials and end products. Compliance is defined differently for the two cases.

- For products:

- Glow wire end product testing (GWEPT), IEC 60695-2-11, is performed on products as sold and how they are expected to be used. This test results in a ‘pass’ or ‘fail’ for the product at a specific temperature. To pass the test, the device under test (DUT) must not ignite or must self-extinguish within a set time and with no charring or ignition of the tissue paper placed under the DUT.

- For materials:

- GWFI, defined in IEC 60695-2-12, is performed by conducting a glow wire test on a sample plate of the material with a specific thickness. The GWFI is the highest temperature at which the material either does not ignite or self-extinguishes within 30 seconds after removal of the heating element, and the tissue paper below the DUT is not consumed in flame.

- GWIT, defined in IEC 60695-2-13, is a second property of the material and is also determined by conducting a glow wire test on a sample plate of the material. It’s the lowest temperature at which the material ignites and burns for over 5 seconds while the heating element is in contact with the test plate. It also requires that the tissue paper below the plate is not consumed in flame.

Passing the glow wire tests

Unattended appliances are set in place and operated independently, with currents greater than 0.2 A, like heating, ventilation, and air conditioning (HVAC) systems and lighting devices. They are subject to the strictest requirements and must pass three levels of flammability evaluation:

- The material must have a minimum GWFI of 850 C° or the end product must pass the glow wire test at 850 C°. If ignition is experienced, the sample must self-extinguish within 30 seconds.

- The material must have a minimum GWFI of 850 C° or the end product must pass the glow wire test at 850 C°. If there is any ignition, it must self-extinguish within 2 seconds. Otherwise, the surrounding components must pass the third level of evaluation.

- The third optional level of evaluation is not performed on the connector but on the surrounding components within a defined space above the connector. Those components must have a material with a minimum flammability rating of UL V1 (defined below). If they don’t meet UL V1, they must pass a needle flame test as defined by IEC (also defined below).

Glow wire testing chambers can be heated to the required temperature and automatically press the heated wire against the material or component being tested with the required 1 N force (Figure 2).

Flame testing

The IEC needle flame and UL 94 tests take different approaches to certify material and product safety. The needle flame test uses a burner with a 0.9 mm tip and butane gas at an angle of 45°. It’s designed to evaluate the hazard of small flames caused by fault conditions. Needle flame tests are evaluated according to the requirements of the specific product standard. For product standards that don’t specify needle flame testing, the generic requirements are:

- The test sample does not produce flames, and the paper does not ignite, or a white pine board does not carbonize.

- After the needle flame is removed, the flame duration of the test sample, surrounding parts, and the bottom layer is less than 30 s, the parts surrounding the test sample does not continue to burn, the paper does not ignite, and a white pine board does not burn.

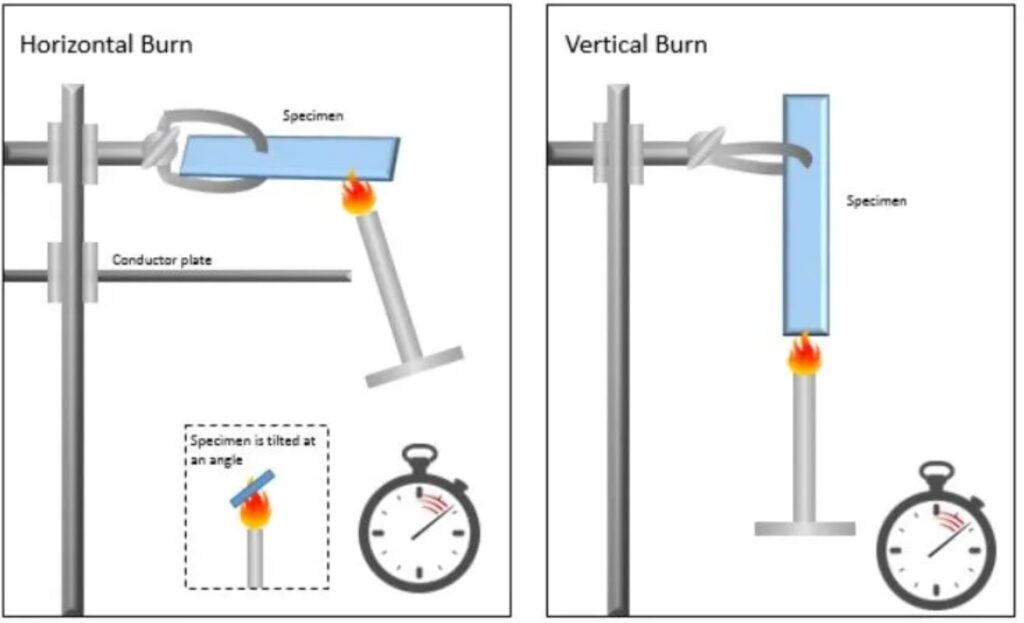

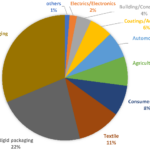

UL 94 is a material burning test and can be a UL94 HB test or a UL94 V test (Figure 3). In both tests, an open flame is applied to the specimen for a set amount of time (see Table 1 below). UL 94 has been harmonized with IEC 60707, 60695-11-10, 60695-11-20, and ISO 9772 and 9773.

UL94 classifications

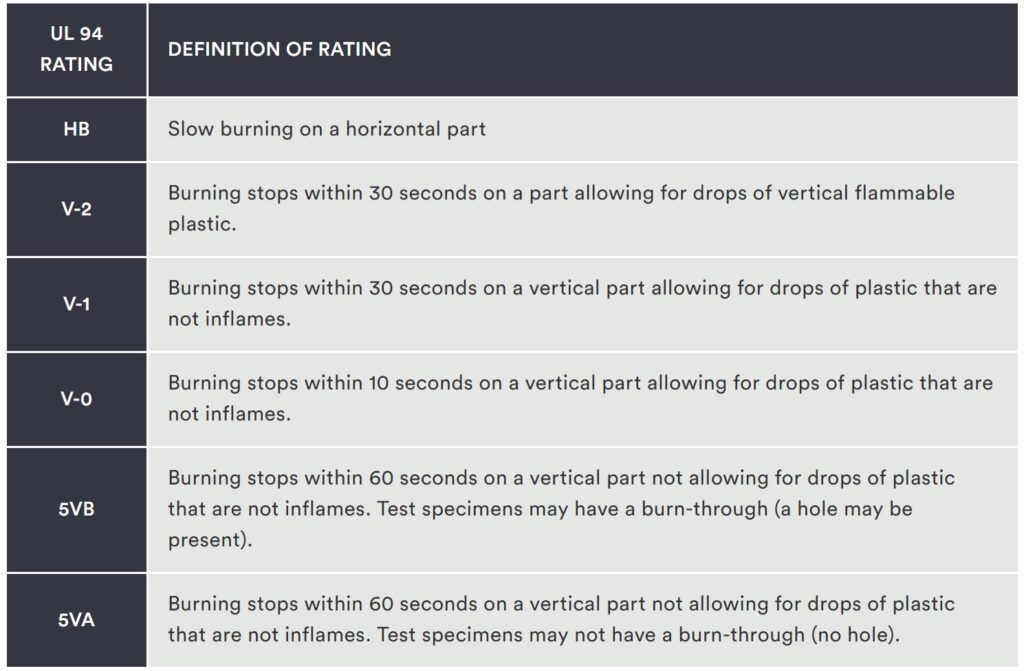

A material having a thickness between 3 and 13 mm will be classified as a UL94 HB (slow burning) material if it has a burn rate of 40 mm per minute or less. For material with a thickness of less than 3 mm, the burning rate can’t exceed 75 mm per minute. The material will also be rated as HB if it stops burning before the 100 mm mark, regardless of thickness. Vertical burn ratings are more nuanced (Table 1). The 5VA or 5VB ratings require testing with a flame ignition source about five times more severe than that used in the V-0, V-1, V-2, and HB. And 5VA and 5VB specimens may not drip any flaming particles.

Testing standards

There are numerous specifications and standards related to glow wire and needle flame testing and how it applies to household appliances and HVAC systems, including:

- IEC 60335-1: 2020: Household and Similar Electrical Appliances — Safety

- IEC 60695-2-10: 2021: Fire hazard testing, Glowing/hot-wire-based test methods — Glow-wire apparatus and common test procedure.

- IEC 60695-2-11: 2021: Glowing/hot-wire-based test methods – Glow-wire flammability test method for end products (GWEPT).

- IEC 60695-2-12: 2021: Glowing/hot-wire-based test methods – Glow-wire flammability index (GWFI) test method for materials.

- IEC 60695-2-13: 2021: Glowing/hot-wire-based test methods – Glow-wire ignition temperature (GWIT) test method for materials.

- IEC 60695-11-5: 2016: Test flames – Needle-flame test method – Apparatus, confirmatory test arrangement, and guidance.

- UL 60335-1 Edition 6.0; 2016: Safety of Household and Similar Electrical Appliances.

Final thoughts

Flammability testing is required for components like connectors subjected to fault conditions that can generate high temperatures, potentially leading to ignition and fires. A range of tests are available, including IEC glow wire, needle flame, and UL burning. The temperatures experienced during glow wire testing can exceed those used for flame and burning tests. In each case, there are a range of possible outcomes with corresponding flammability classifications.

References

Combustion (Fire) Tests for Plastics, UL

Glow Wire Test and Needle Flame Test to Evaluate the Flame Resistance of Plastic Materials, Gester Instruments

Glow Wire Testing and Evaluation Overview, Molex

Glow Wire Testing for the Appliance Industry, TE Connectivity

What you need to know about UL Classifications?, Antala Specialty Chemicals

UL 94 Classification and Flame-Retardant Thermoplastics, Protolabs

Leave a Reply

You must be logged in to post a comment.