Consumers purchase counterfeit products everyday, such as handbags and watches. And while it doesn’t hurt the consumer, the biggest issue with counterfeit goods comes in the loss of intellectual property and money to the real designers. Not so with counterfeit connectors. While it may save the buyer money in the short term, purchasing counterfeit connectors not only hurts the real engineers and companies who have designed them, but it can also be downright dangerous—to your machines and to the people that interact with them.

Although all connector designs could be copied, you may find the most commonly used designs more at risk. M12, M8, 7/8 in., M12 splitters, M12 junction boxes, and circular pin-style connectors are the most popular type of industrial connectors frequently copied, as are telecom (RJ style), fiber and other power products.

Here are a few tips to avoid purchasing these fakes.

1. Know your suppliers

Perhaps the simplest solution to avoiding counterfeit connectors is to buy only from authorized distributors. Brian Krause, global marketing and communications, Molex Inc., advises users to only purchase connector products through companies authorized by the manufacturer. “Check with the manufacturer for a complete list of companies authorized to sell their products,” Krause said. “In most cases the manufacturer’s website will highlight those companies and provide current contact information.”

Also, Krause added, “for most companies, power and data are resources to be monitored and protected. Avoid purchasing or putting into service any connector components of dubious origin.”

2. Check the certifications

Krause and Dave Gallagher, product manager at L-Com, both stress the importance of product certifications. Checking UL, ETL, NEC and other numbers on a product is one way to confirm authenticity.

The same goes for cordsets. Turck insists that cordsets must meet IP ratings. In applications with moisture and ingress protection, if the connector will not hold up to requirements demanded of the application, there will be problems.

3. The cost is clear

If a price seems too good to be true, it probably is. L-Com’s Gallagher said that a great price usually means something is missing. And on the opposite end of the spectrum, a highly expensive component does not necessarily mean it’s going to be a better product, either, he added.

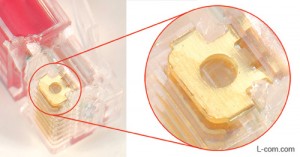

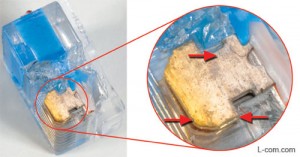

4. Solid gold vs. minimal plating

If you’ve already purchased a component that might be counterfeit because the first three flags above weren’t raised, there are a few things you can look for to see if the product is safe. Krause cautions that gold plating can be false. He suggested you verify gold plating thickness, which would be among the first ways that counterfeiters cut corners. Gallagher added that some counterfeiters might send in a legitimate sample, then when a purchase is made, you get a different product. Krause added, “If in doubt, always consult a reputable manufacturer to verify authenticity.”

Likewise, Turck said cordsets and cables need to be similarly inspected. With cables, function is a sure sign the cable is legitimate. For example, is the material really as advertised (i.e. PVC, TPU/PUR) and does it look and feel as described? If it does not work as advertised in flexing or corrosive applications, or if jacketing cracks, you more than likely have a fake on your hands. In addition, Turck recommends checking the stainless-steel housings and coupling nuts on a cordset. If it is not 316 stainless steel, as is required in some applications, the steel (such as 303 or 304) will corrode.

Leave a Reply

You must be logged in to post a comment.