The HARTING Technology Group continues forging ahead with new products and solutions for Integrated Industry. One example — its own smart factory called HAII4YOU Factory — proves that Integrated Industry is no longer just a vision, but already a concrete reality. HARTING will be exhibiting at Hannover Messe, April 24-28 in Hall 11, Stand C15, with its motto for this year’s Hannover Messe, “Integrated Industry – Creating Value.

“We want to increase customer benefit. Using our products and solutions, customers can run their industrial processes more efficiently,” explained Chairman of the Board Philip Harting at the HARTING trade press conference fronting the Hannover Messe preview. Along with other items, HARTING will be exhibiting smart Han products and further MICA applications. There will also be a major focus on e-mobility.

HARTING will highlight its three miniature heroes: HARTING ix Industrial, HARTING T1 Industrial and M8 D-coded.

New this year is Miss M8ty delivers standardised M8-coded and investment-proof fast Ethernet. The name comes from M8 D-coded, which HARTING has developed to assist device manufacturers in the current trend for miniaturization.

Sensors, camera systems and switches are just a few of the components that are being prevented from further miniaturization — and only because of the limitations of the connection technology. But current developments are addressing not only size but standardization and digitalization, too. Even the smallest field components need to be connectable to super-ordinated networks — and speak just a single language: Ethernet. In the past, the problem has been that all Ethernet connectors suitable for IP65/67 environments have been too big, standing in the way of miniaturization.

Miss M8ty solves this problem: HARTING calls this component a “slim and elegant” end-to-end Ethernet solution — from the cloud to the smallest sensor. With up to 100 Mbits and PoE, the veM8 D-coded provides all consumers with power and data via a small interface, doing away with the previous BUS systems.

The new PushPull V4 Industrial is made of a new housing material that is also resistant to aggressive chemicals, has a locking system and a more flexible cable connection. Along with further innovative features, this provides users with greater process reliability, making it suitable for demanding application environments. PushPull V4 Industrial is designed for power, signal and data.

The new housing material makes it more resistant, even to aggressive operating resources, and a locking device prevents it being pulled out by mistake. The standardized cable crimp is another new, simpler feature that now works with a single seal instead of the previous three. Plus, the ability to accommodate greater cable widths and easy and reliable handling combined with robust build mean greater dependability and process reliability for customers.

HARTING has developed a new pneumatic module — the Han Pneumatic Module Metal — to meet increased demands on interfaces for more flexible construction. It uses robust, long-lasting metal contacts and can be pushed and pulled at least 10,000 times. The new module gives users the option of compressed air, even in situations where production equipment often has to be reconfigured for supplying drive and control units, brakes, holding and unloading units, for example.

The new interface offers a high maximum operating pressure level: instead of the previous upper limit of 8 bar (Han Pneumatic module with plastic contacts), contacts can now withstand pressure up to 10 bar permanently. This means that Han Pneumatic Module Metal now covers the entire low pressure range, extending the possible applications for pluggable compressed air systems.

HARTING has used flow simulations to minimize contact pressure loss. Pressure loss in the socket contacts with internal valve is now half that of conventional pneumatic interfaces. This innovation also opens up new combination possibilities for pneumatics in modular connectors for high connection cycles (HMC): electrical contacts for the transfer of signal and power can now be combined with contacts for the transfer of light waves and compressed air in HMC connectors for the first time –—saving users valuable build space and assembly time.

“This innovation enhances the performance of the existing Han-Modular range of over 100 individual modules, which is being continually adapted to the needs of industry,”said André Beneke, Director Product & Industry Segment Management at HARTING Electric.

HARTING also introduced the new Han-Modular Docking Frame Metal. This enables control cabinet machine modules and drawers to be docked on to their supply with plenty of room for maneuverability and a high level of accuracy. This saves customers time and money, as the frame is built in such a way that it works without an additional articulated frame, and can be fitted directly to connector modules. This opens up the entire HARTING connector range of over 100 different modules.

Its particular mechanical stability means that it provides sufficient reliability for all kinds of application. The system enables machine components to be switched quickly and reliably. Slide-in modules in low-voltage switch gears can be supplied with signal and data and energy storage units with power and data cost-effectively.

The HARTING MICA Energy measuring system will have its first official unveiling at Hannover Messe 2017. MICA Energy enables energy data to be collected from existing machines easily and cost effectively. Data can be introduced to both MICA and proprietary solutions.

Eight partners from the MICA.network will also be presenting their solutions for production digitalization and IIoT (Industrial Internet of Things) at Hannover Messe. The emphasis will be on retrofit solutions, where the cost benefits are seen very quickly.

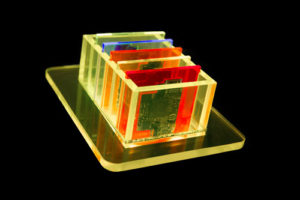

HARTING is already considering further developments for MICA, as evidenced by the miniMICA concept, which has enhanced this year’s “Oasis” concept vehicle from Swiss ideas factory Rinspeed AG. miniMICA has been given a scalable and flexible architecture, enabling computing elements to be connected in a range of different ways. With the “Oasis,” the driver can customize the pluggable modules and system configuration to the task in hand.

Caption: The new HARTING M8 is a robust miniaturised solution – from the Ethernet to the smallest field application.

Caption: miniMICA has been used in “Oasis” – the concept vehicle from Rinspeed.

Caption: The new Han® Pneumatic Module Metal allows compressed air transfer via modular interfaces for thousands of connection applications.

HARTING Technology Group

www.HARTING.com

Leave a Reply

You must be logged in to post a comment.