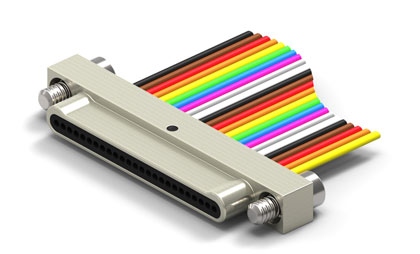

Nanominiature or nano-D connectors are offered as both rectangular and circular high-density assemblies. Most of these tiny interconnects use twist pin contact technology to provide a reliable connection even in harsh conditions that encounter shock and vibration, all with low separation force and engagement. Those manufactured by Ulti-Mate use a stamped and formed contact system rather than the twist pin style.

Most nano-D connectors are based on MIL-DTL-32139 specification for use in aerospace and military applications. Other common applications requiring this miniature connector design include medical, offshore, industrial control and robotics.

Offering an extremely low profile, they feature contact spacing of 0.635 mm or 0.025 in. For consistent reliability, nickel/gold-plated contacts are recommended. Copper alloys, stainless steel, and other plating materials are available but do not perform as well.

Nanominiature shells are commonly manufactured of aluminum, titanium, nickel and stainless steel. Plastic shells made of liquid crystal polymer are also available. Common shell styles are available as rectangular and circular, for countless mounting styles including horizontal SMT, PCB right-angle SMT and thru-hole, straight flange mount, and right-angle PCB mount, among others.

Several newer designs are offered as hermetically sealed for high-pressure applications requiring low leakage.

Hello Mary,

I noticed you used a wired nano image from Ulti-Mate Connector Inc. Thank You!

However the body of your write identities twist pin. Ulti-Mate uses a superior stamped and formed contact system within our microminature products.

Thank you, Frank, I have updated the text to make note of Ulti-Mate’s designs!