Since first coming up with the idea of the Power Control Room (PCR ) in 1968, Powell has been recognized as a market leader in modular electrical equipment design. By utilizing innovative products in the design and construction of these PCRs, they improve quality and productivity while lowering costs and reducing labor. Used in a wide range of markets from utility substations to oil/gas projects to transportation systems, these PCRs have been transported and installed in all 50 states and over 70 countries.

Since first coming up with the idea of the Power Control Room (PCR ) in 1968, Powell has been recognized as a market leader in modular electrical equipment design. By utilizing innovative products in the design and construction of these PCRs, they improve quality and productivity while lowering costs and reducing labor. Used in a wide range of markets from utility substations to oil/gas projects to transportation systems, these PCRs have been transported and installed in all 50 states and over 70 countries.

The size of the PCRs created by Powell varies depending on the final application. “Some are so large they need to be split apart and shipped in sections,” Powell Production Designer Rick Deiss explained. When Powell assembles these larger Power buildings, the sections (or rooms) are first physically joined together. Then the interconnect wiring between each building must be reliably terminated during the manufacturing phase and subsequently “de-terminated” before the buildings are split apart again so they can be shipped to the final job site. Each section typically includes shipping split boxes for wiring. In the past, when these boxes were shipped, wires would sometimes become loose due to vibration or through installation errors, which created obvious safety and reliability concerns. Therefore, upon delivery, prior to connecting the rooms together, engineers would need to go into each box, reconnect the wires, and re-tighten the screws that held the wires in place using calibrated torque screwdrivers. This made the process both costly and time-consuming as these specialty tools carry not only a high initial investment but require calibration annually.

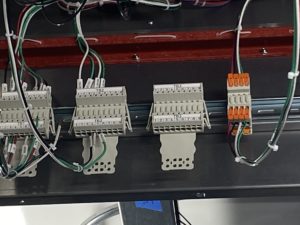

For mounting connections, Powell had previously used an internally-fabricated aluminum angle bracket modified with 7 pre-punched square-mounting holes which would allow a third-party, 2-piece pull-apart terminal block assembly to snap into each square hole. This design, however, was considered labor-intensive and could cause reliability issues, as the connectors would sometimes become dislodged from the mounting bracket. They began to look for ways to improve their design while simultaneously gaining a higher-quality connection. “We needed a terminal block for power connections that could be disconnected by pulling it apart,” Deiss said.

In 2016, Ciarah Tapley-Smith of Future Electronics, WAGO’s local distributor in Houston Texas, along with WAGO Regional Sales Manager Kevin Stevenson, arranged a visit to Powell by WAGO’s Innovation In Action Tour (IIAT) mobile display. It was then that they were introduced to WAGO’s exclusive Cage Clamp design technology. With hands-on demonstrations, they were able to experience for themselves that this innovation in wiring would be the answer they were looking for. Specifically, they were shown the 831 Series connectors and learned how they could improve their connections integrity while reducing production and labor costs.

WAGO’s Region Sales Manager, Kevin Stevenson who was on hand when Deiss and his associates saw the innovation recalled, “They saw us demonstrate the 831 Series connector as a means of quickly connecting power and control circuits and were impressed.” Powell requested samples to see if the connectors could indeed fit their company’s specific application needs. Deiss pointed out that he and his colleagues were also able to visit WAGO’s manufacturing and testing facilities in Minden, Germany to learn more. “The 831 Series connectors are just what we needed,” stated Deiss, “while touring the WAGO factory in Germany, I saw parts being manufactured as well as many tests performed on their products. I was amazed by the quality of their products and how well they held up to the grueling testing.”

Powell soon realized that the 831 series would prove to be an innovative component in the manufacturing of their PCRs. This would empower them to offer more value to their customers and remain an industry leader. “It was evident by their implementation of our original tool-operated, DIN-rail mounted 831 Series that they value our connection technology and form-factor not only as a time/labor savings but also for the improved connection integrity it provides,” says Cory Thiel, WAGO’s PCB Interconnect Product Manager. Since their partnership with WAGO, Powell has eliminated the cost of lugs and the labor for crimping as well as the need for the pre-fabricated aluminum mounting bracket. With the use of spring pressure connection technology, there are no screws, thus eliminating loose connections and the need for torqueing. These products have sped up the process of manufacturing, connecting, and disconnecting the shipping splits, ultimately reducing labor costs.

Over the last four years, both Powell and WAGO have developed more innovative solutions to help with the production and shipping of Powell’s Power Control Rooms. That, along with Future Electronics’ commitment to keeping WAGO products in stock, further aids Powell’s trust and reliance on WAGO’s strong distributor supply chain network So what may be on the horizon? WAGO is currently producing a new version of the 831 series with tool-free lever actuation. Powell is also looking at using WAGO’s new 832 Series connectors to replace additional competitive devices and some old connections that need larger wire connectors.

“Powell is looking to implement more of our products in their design and are very excited to hear that we will soon have the 832 Series connectors coming out later this year with a DIN Rail-mount capability,” Stevenson said, “which will allow them to use our Cage Clamp technology on larger wiring circuits ranging up to 4 AWG.”

“With the introduction of the larger 832 Series and its mounting adapter,” added Thiel, “Powell can take an even greater leap in their production throughput and reliability improvements across an even greater scope of their PCRs”

Deiss also expressed his enthusiasm for the future between Powell and WAGO, “I am very excited about the 832 Terminal Blocks. These have larger ampacity ratings so we will be able to pull apart connections for up to #4 gauge wire. Currently, wiring larger than #8 requires lugs, screw terminations, and torqueing.” With the help of these products, Powell will continue to work on speeding up and simplifying the wiring process, all while remaining the standard-bearer for electrical equipment design.

WAGO

www.wago.com/us/

Leave a Reply

You must be logged in to post a comment.