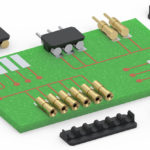

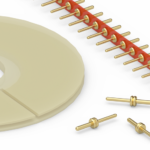

Mill-Max Manufacturing Corp., Inc. today announces four new pins specifically designed for press-fit into PCB plated-through holes, providing a secure connection while maintaining plated-through hole integrity and continuity. These new PCB pins incorporate square press-fit geometry and angled vent features making them suitable for solderless press-fit or press-fit and solder PCB termination.

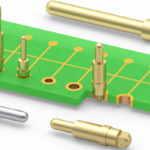

The four pins presented here are double tail header pins featuring a square press-fit shank, a round tail and a standoff body in between. When these pins are pressed into a plated through-hole the points (the major or circumscribed diameter) of the square are set or embedded in the hole while the flat sides of the feature (minor or inscribed diameter) provide relief, allowing the remainder of the plated through hole barrel to remain intact. The result is internal board layers are not disconnected when the pin is pressed in. With a properly specified hole size, the polygon shaped press-fit feature will allow the pin to be secured in the hole while maintaining continuity throughout all the layers of the PCB.

The four pins presented here are double tail header pins featuring a square press-fit shank, a round tail and a standoff body in between. When these pins are pressed into a plated through-hole the points (the major or circumscribed diameter) of the square are set or embedded in the hole while the flat sides of the feature (minor or inscribed diameter) provide relief, allowing the remainder of the plated through hole barrel to remain intact. The result is internal board layers are not disconnected when the pin is pressed in. With a properly specified hole size, the polygon shaped press-fit feature will allow the pin to be secured in the hole while maintaining continuity throughout all the layers of the PCB.

Often, these pins are used as the output terminals in applications with more demanding mechanical/electrical requirements such as power supplies, power converters, rectifiers, relays and any device subject to blind mating or rough handling. The press-fit end terminates to a board inside the device while the exposed tails are typically plugged into sockets or soldered into PCB holes by the user. In the latter case, vents located at the pin end allow soldering gasses to escape enabling better solder flow. Another common use for these pins is in board stacking applications, particularly those used in power environments. Mill-Max employs advanced machining technology to manufacture pins with exact press-fit features to suit a variety of hole sizes and assembly requirements along with precise body lengths to deliver consistent, controlled standoff heights between boards.

Mill-Max

www.mill-max.com/pr689

Leave a Reply

You must be logged in to post a comment.