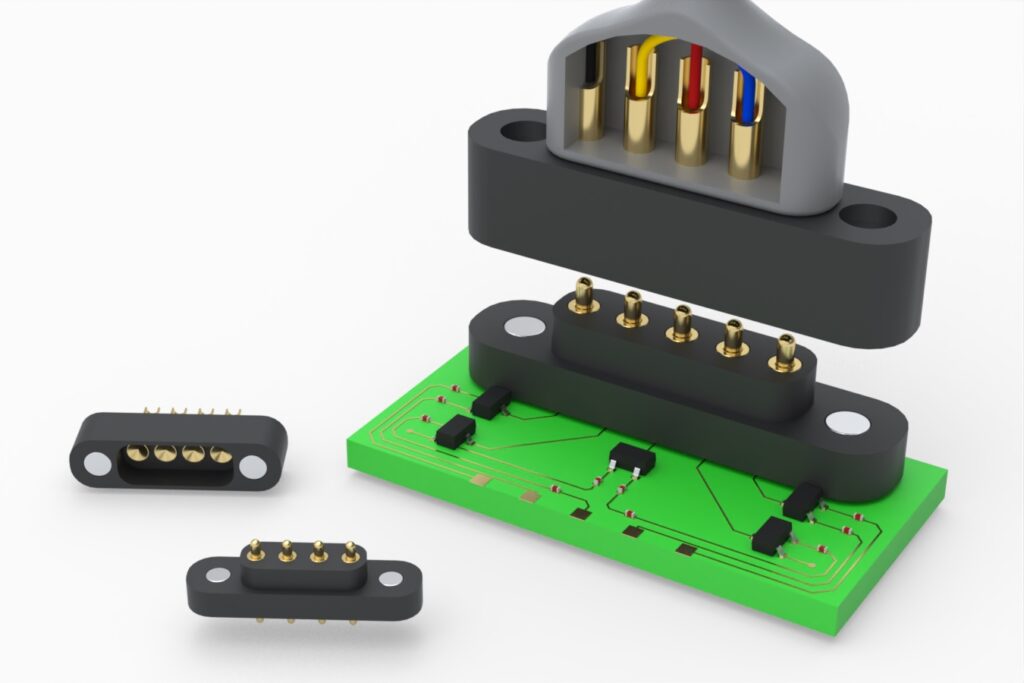

Mill-Max Manufacturing Corp., announces its first magnetic mating connectors. The Maxnetic™ spring-loaded connectors are designed to make connecting components effortless, reliable, and durable. This series of magnetic connectors feature self-alignment, self-location, and zero force mating, in response to the growing field of applications requiring connections to be made quickly and easily.

Mill-Max Manufacturing Corp., announces its first magnetic mating connectors. The Maxnetic™ spring-loaded connectors are designed to make connecting components effortless, reliable, and durable. This series of magnetic connectors feature self-alignment, self-location, and zero force mating, in response to the growing field of applications requiring connections to be made quickly and easily.

Maxnetic™ spring-loaded and mating target pins establish an electrical connection as the magnetic force pulls and holds the connectors together; no aligning or plugging is required to mate the connectors, and no hardware is needed to keep them mated. These attributes make magnetic connectors attractive for use in medical environments with repeated mating and un-mating of cables into devices and with portable device docking/charging stations by enabling quick connections, blind mating, and the ability to break away for emergency release without damage to the components.

The products are introduced with a connector pair consisting of a through-hole PCB mount spring-loaded connector (P/N: 878-22-00X-10-011101) and a shrouded target connector with solder-cup terminations (P/N: 878-20-00X-00-011000); the combination is ideal for cable to device applications.

The connectors are single row, 2-6 positions, with a pin-to-pin spacing of 4 mm (.1575”). The spring-loaded connector has an above-board height of .378” (9.6 mm) and contains spring-loaded pins featuring .090” (2.3 mm) maximum stroke, the cycle life of up to 1,000,000 cycles, 25 milliohms contact resistance, *7.2 amp per pin current rating, and gold plating on all components. The target connector is shrouded to ensure alignment and engagement with the mating spring-loaded connector and has gold-plated solder cup pins that accept up to 16 AWG wire. The use of strong, long-lasting neodymium (NdFeB) magnets on both connectors provides 1.4 pounds (636 g) average separation force (1 pound (454 g) minimum) and enables the connectors to be pulled into alignment and connect with each other at up to .500” (12.7 mm) apart. The connectors can be used for power or signal transmission and may be mounted in vertical or horizontal orientations. Optimal electrical and mechanical reliability is ensured using high-quality Mill-Max spring-loaded pins.

Leave a Reply

You must be logged in to post a comment.