When selecting components for their applications, mechanical and electrical engineers, must understand some general guidelines for their PCB interconnect requirements. Below is a short list of nine of the most common and cost-effective pin retention designs and where they may be used. Press-Fit Barb — is specifically for non-plated through holes. This is the easiest and […]

preci-dip

What are the benefits of screw machine interconnects?

As Principal Engineer for a large connector manufacturer, each day I am challenged by electrical engineers and mechanical engineers to help bridge their leading edge technology from one module to another. I remember years ago, when the pin grid array went obsolete to the emerging QFP quad-flat pack, people said that “screw machine was a […]

When should you use press-fit screw machine header pins?

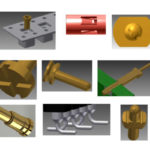

Continuing the discussion on screw machine technology, here is a look at this technology, the advantages of using it and how to best utilize this technology in your engineering projects. Below is a list of the common styles of press-fit screw machine header pins: Press-fit barb has a fishhook shaped feature, typically featuring 15° angle. It runs […]

How are multi-finger contact clips used in screw machine receptacles?

Typically inside every screw machine socket receptacle is a precision die stamping called a contact clip. Contact clips are usually stamped using beryllium copper (for conductivity) or beryllium nickel (for elevated heat applications). These stampings are press-fit into machined brass shells and function as the electrical and mechanical interface to a mating pin. Contact clips […]