Connectors are complex assemblies whose performance is based on interactions of electrical, mechanical, environmental, and materials factors. Extensive testing is required to ensure proper performance, and numerous industry standards have been developed for that purpose.

This FAQ reviews 13 tests across three key performance indicators for connectors, including electrical, mechanical, and environmental considerations for connectors used in heating, ventilation, air conditioning (HVAC) systems, and other harsh environments. Some aspects of materials testing for connectors are discussed in the FAQ on “What’s the Difference Between Needle Flame and Glow Wire Testing?”

Testing is the cornerstone for quantifying the performance of connectors in challenging environments. Three key areas are:

Electrical tests: The impact of high current and temperature rise poses challenges to components. Testing should evaluate wet insulation resistance, current carrying, impulse withstand, contact resistance, and other factors.

Mechanical tests: Flexion testing, conductor pullout, cold impact, protection against contact, and low-level contact resistance are several basic mechanical considerations.

Environment tests: degree of protection, vibration, humidity, corrosion, and temperature shock, including Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screen (HASS) testing.

Whether testing is performed in-house or at an independent laboratory, the requirements of ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories, should be met. Accreditation is mandatory for testing performed as part of regulatory compliance. The need for accreditation applies to all tests, including electrical, mechanical, environmental, etc.

Electrical performance

Electrical performance testing is a broad area and can include a wide range of tests, a few of which are discussed in more detail below. Representative tests include:

- Contact resistance measurement (IEC 60998-2-1)

- Clearances and creepage distances (IEC 60601)

- Current carrying capacity derating curve (IEC 60512-5-2)

- Cyclical overload test (heat-cycling test according to UL 1059)

- Cyclical aging test

- High-voltage test

- Impulse withstand voltage test (IEC 60664-1)

- Insulation resistance (UL 1703, UL27)

- Resistance measurements

- Thermal reliability

Contact resistance is a basic connector performance specification. Bulk resistivity, or intrinsic resistance, describes the resistance of a material of a given size and area. Contact resistance, on the other hand, describes the resistance experienced when two conductors come into contact (Figure 1). IEC-60352-5 requires that contact resistance testing be carried out using the millivolt level method specified by IEC 60512-2-1. Contact resistance is a complex phenomenon affected by constriction, film resistance, and stress relaxation. Constriction describes the narrowing of the true contact surface when two materials meet. Film resistance is the resistance created by unwanted resistive material (film) on the surface of the contact. Contact deformation can occur over time, changing the shape of the contact as a result of stress relaxation.

Current carrying capacity should be measured by IEC 60512‑5‑2. Current carrying capacity is limited by the insulating parts of the connector housing and the thermal properties of the contact materials. It is dependent on the ambient temperature and self-heating of the contacts. The tests quantify carrying capacity versus ambient temperature.

Impulse withstand voltage test should be performed by IEC 60664‑1. This is an indirect test that the design has sufficient creepage and clearance distances for safe use. The magnitude of the test voltage is based on the rated surge voltage of the connector. The test uses three voltage surges (1.2/50 µs) per polarity. To pass, there must be zero spark overs.

Wet insulation resistance test, as described by UL 1703 and UL 27, is an important test for connectors used in outdoor applications like some HVAC and industrial systems. The standard requires that these connectors withstand wind and weather for up to 25 years. Wet insulation resistance testing provides a quantitative measure for insulation performance. Performing the test in a still conductive aqueous solution enables the identification of changes in the air clearances and creepage distances that hairline cracks and other difficult-to-identify sources may cause.

Mechanical performance

Mechanical performance testing is another broad area that includes a range of tests, a few of which are discussed in more detail below. Representative tests include:

- Cold impact test (UL 746C, 57/UL 1703, 30)

- Conductor connection capacity

- Conductor pullout test (IEC 60998-2-1)

- Drop test

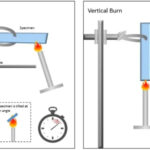

- Flammability and fire resistance test (UL 30, UL 57, UL 1703)

- Flexion test and bending test (IEC 60999-1)

- Impact test (UL 746C)

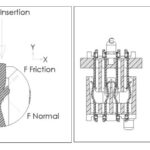

- Insertion and withdrawal force (IEC61210)

- Lock-in position of electrical contacts

- Number of plugging cycles

- Touch-proof protection (IEC 60529)

Conductor pullout test in accordance with IEC 60998‑2‑1. Applies a specified tensile load on the terminal point for one minute, and the conductor must be held in position without damage. This test is performed after the flexion test (described below) and is a stricter requirement.

Cold impact test as described in UL 746C, 57/UL 1703, 30. Is performed after storing the connectors to be tested at -35°C. The test consists of dropping a test weight on the connector with a defined impact energy. This test can cause the creepage and clearance distances in the connector under the test to change. As a result, a test of creepage and clearance distances should be performed following the cold impact test.

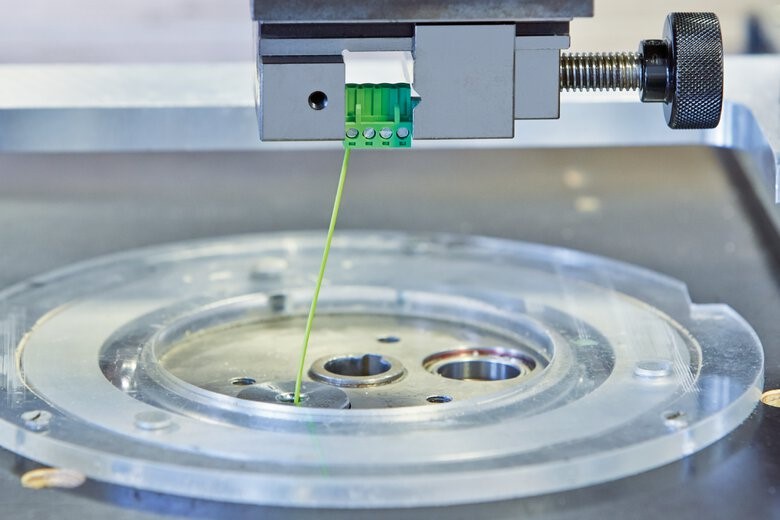

Flexion test, or rotation test, is detailed in IEC 60999‑1. A conductor is attached to a vertically fixed connector, and a test weight determined by the connector cross-section is attached to the opposite end of the conductor. The conductor is fed through a 37.5 mm circular hole in a rotating disc spun on its horizontal axis 135 times (Figure 2). Following the test, the contact must pass the IEC 60998-2-1 pullout test.

Touch-proof protection testing in accordance with IEC 60529 ensures that the connector design provides a high level of safety from live voltages to technicians when the equipment is being serviced or maintained. The test uses a test probe or ball placed on each connector opening with a specified force.

Environmental performance

Environmental performance testing is an important area of testing for systems like HVAC or industrial equipment that may be used outdoors or in harsh environments. Five of those tests are discussed in more detail below. Representative tests include:

- Corrosion tests: Salt-spray test, SO2 test, condensation climate, flowing gas mix (IEC 6988)

- Degree of protection tests (IP classification) in accordance with DIN 40050-9-60529

- Dust test for an electronics housing

- Humidity

- Temperature range

- Temperature shock

- Vibration tests: Sine waves, resonance search, mechanical shock, broadband noise (IEC 60068-2-6)

Corrosion test defined in IEC 6988. Gas-tight connections are required to pass this test with corrosion-free and low contact resistance when exposed to salt spray and other aggressive materials. The Kesternich test involves exposure to a sulfur-oxidic atmosphere at an ambient temperature of +40°C. After a subsequent drying period, a visual inspection is performed, and the contact resistance is measured.

Degree of protection test in accordance with DIN 40050‑9/60529 measures the ingress protection (IP) level of the connector by testing its performance when exposed to water, including immersion and high-pressure sprays, and particles of various sizes, including fine dust.

Humidity testing is conducted in combination with other qualification tests, including mating and unmating, low-level circuit resistance (LLCR), and insulation resistance/dielectric working voltage (IR/DWV). Humidity testing is usually performed in a purpose build test chamber (Figure 3). It exposes the mated connector set to varying temperatures, from 25 to 65 °C, with a humidity range of 90% to 98% RH over ten days. The connector must pass mating/unmating, LLCR, and IR/DWV testing after the humidity and temperature cycling to pass the humidity test.

Temperature shock testing, defined in IEC 60512‑11‑4, test 11d, is important for industrial applications and HVAC systems. To simulate rapid temperature changes, a two-chamber test is often used. The connector under test is moved between two chambers, one at the lower temperature limit and the other at the upper-temperature limit, within a few seconds, remaining in the second chamber for 45 minutes. To pass the test, the connector’s overall functionality must be unimpaired.

Vibration testing includes harmonic and sinusoidal vibrations as defined in IEC 60068‑2‑6. Various combinations of vibrations are applied to the connector along all three axes to simulate oscillating, pulsating, or rotating forces. Typical vibration frequencies range from 10 to 2,000 Hz and are successively applied at a rate of one octave per minute. To pass the test, the functionality of the connector must be unimpaired.

Summary

Testing is important to ensure reliable and safe operation of connectors in harsh environments and applications like HVAC systems. Electrical parameters, mechanical specifications, and environmental tolerance are key factors in connector performance. Accreditation to ISO/IEC 17025, which details the general requirements for the competence of testing and calibration laboratories, is an important consideration when testing is performed as part of a regulatory compliance program.

References

ISO/IEC 17025 Testing and calibration laboratories, International Standards Organization

Mechanical tests for connectors and electronics housings, Phoenix Contact

Severe Environment Testing for Connectors, Samtec

Understanding Connector Contact Resistance, ATL Technology

Leave a Reply

You must be logged in to post a comment.