Wouldn’t system design be a lot easier if everything were in one box, on one board? The schematic becomes the board design and the world can be much simpler. One pass through the SMT line, test the box, and ship. Connectors seem to only complicate the situation because they:

- Add a point of failure in the system

- Complicate system design and can lengthen design cycles

- Cost money

- Need to be applied to the board or cables, adding additional cost and complexity

- Add to the bill of materials to be procured, stored, and potentially scrapped if a design is changed

A very wise man, Don Wilson, formerly of Bellcore, the organization that for many years wrote standards for telecom connectors, gave me the best answer to this question I have ever heard:

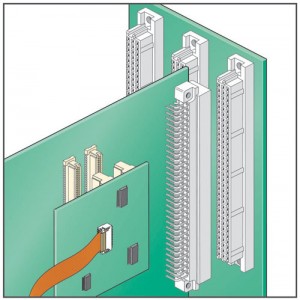

It is desirable to partition systems into pluggable units because it allows:

- Board manufacturers to sell their boards into many different systems.

- The systems engineer to specify boards with the functionality he needs

- The purchasing department can source boards from multiple suppliers, assuring competitive pricing and continuity of supply

The system can be offered in configurations that best match the needs of the end user, such as:

- Processors

- IO (Input Output) configurations

- Cabinet size and configuration

- Memory and hard drive options

Having pluggable units also facilitates system trouble-shooting, repair and spare inventory because:

- Most users can remove and replace a pluggable unit. If it works, it is fixed. If not, you move on to the next step on the troubleshooting list.

- A few processor spares or memory cards can support an entire Google size data center, minimizing down time and cost.

The pluggable units can have dramatically different manufacturing processes, such as:

- Some boards are high layer count with complex functions

- Others are very simple and cheap to make—maybe even an off-the-shelf commodity

- Cables come from different sources than boards

- Cables can be copper or fiber

- Cable lengths can be selected for proper fit

It often happens that a design is optimized for semiconductors that are still in development. Having these chips on pluggable units allows the OEM to plug in boards with current technology now, upgrading to the latest and greatest semiconductors when they are released and proven to work.

Fear of failure is a major driver for any designer. By designing with pluggable modules, risk is greatly reduced, ensuring that you meet time-to-market targets while still having the advantage of plugging in the latest and greatest technology as it becomes available.

Don described connectors as “Disconnectors” that allow for optimizing system design to best match the needs of the end application. Without disconnectors, there would be a lot more design time, risk for time-to-market, quality, and cost. I guess connectors will be around for a while longer.

Leave a Reply

You must be logged in to post a comment.