The Space Splice system from C&K/Littelfuse can reduce the time needed to build cable assemblies with crimps and connector housings.

The Space Splice system from C&K/Littelfuse can reduce the time needed to build cable assemblies with crimps and connector housings.

Building custom wiring harnesses is time-consuming, especially when you must splice wires and tie them together. The Space Splice series from C&K/Littelfuse can reduce assembly time in production.

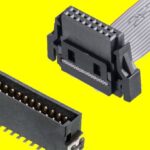

Instead of twisting and soldering wires, assemblers can crimp pins to wires and simply connect them to housing. The Save Splice series consists of plug and receptacle D*MA pins that you can crimp to bare wires, then insert the plug into a socket (see image). If you need to break the connection, simply pull the pins apart.

To keep the connections secure, you can make the connection by sliding the pins into a sleeve for a single connection or housing for up to four connections. The housings can then be screwed onto a board or stacked and then screwed together for board or free-floating use. You can also panel-mount a housing as the image shows.

The Space Splice system supports AWG20, AWG22, AWG24, AWG26 and AWG28 wire sizes. It complies with ESCC specifications 3401/097 Connectors and 3401/005 Removable Crimp Contacts. You can use connectors with voltages up to 300 Vrms for single connections or 250 Vrms for four-way connections. Rated current is 7.5 A for AWG20 and 3.0 A for AWG26 wires. Contact resistance is 5 mΩ with insulation resistance at 50 MΩ.

Littelfuse claims that the Space Slice system saves 5 to 10 minutes per splice. According to the company, a typical hand splice process includes six steps and a wire cutter, solder, and hot soldering iron.

- Pre-tin the wire conductors

- Lash the conductors

- Solder the lash splice

- Inspection

- Sleeve the connection

- Quality assurance certification

SpaceSplice requires only three steps and two tools — a wire cutter and a crimping tool:

- Crimp contacts

- Set the contacts into the SpaceSplice

- Inspection

Leave a Reply

You must be logged in to post a comment.