Space-grade connectors are generally spin-offs of military-grade designs. Compared with common commercial connectors, there’s a much smaller variety of space-grade connectors. However, commercial off-the-shelf (COTS) and COTS+ connectors are increasingly used in cost-sensitive missions such as CubeSats. This FAQ begins with a look at the unique operating conditions in space and how those conditions impact […]

Four types of connectors for robots and drones

Many power and signal connectors are used in robot and drone sub-systems, such as sensors, motion, high-speed wired and wireless communications, and more. As industry 4.0 continues to unfold, more robots and more types of robots are being found in factories, warehouses, and other facilities to increase quality and efficiencies and reduce costs. Robots and […]

What are 1-phase and 3-phase AC power connectors & standards?

Power connectors are primarily designed to ensure a safe and reliable connection of devices to AC mains power, although they are generally specified for AC and DC voltages. AC receptacles and plugs come in various configurations with different blade widths, shapes, positions, and dimensions, designed to make them safe to use and non-interchangeable with different […]

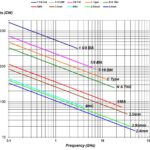

Six key considerations when selecting and integrating GHz connectors into 5G applications

Connectors are essential components in radio frequency (RF) systems, especially in high-frequency applications like Gigahertz (GHz) 5G devices. Designers have a broad range of connectors to choose from, but there are a few key parameters to consider when narrowing down the choices. Six keys to selecting and integrating GHz connectors include physical size, frequency range […]

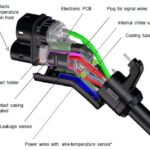

Why and how are medical connectors and standards different?

Medical connectors are different because medical applications are different. Medical systems require high reliability like industrial systems, but they have unique challenges where failure or unreliable operation can be life-threatening. A few examples include: Materials qualified for medical connectors are often specified to prevent bacteria growth and ensure that the connection system withstands sterilization or […]

What’s the status of EV charging connector standards?

Connectors for electric vehicle (EV) charging are both standardized and changing. On one level, EV charging connectors are standardized based on today’s technology limitations. There are standards in major regional markets, including North America, Japan, the European Union, and China. But current charging technologies are power limited. This FAQ begins with a review of EV […]