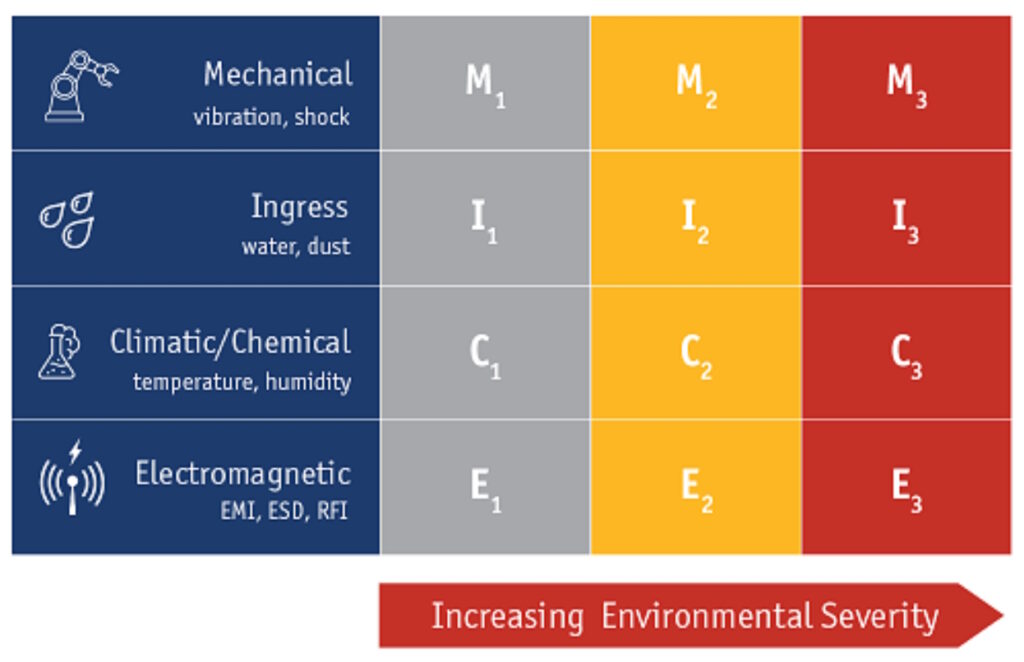

IEC 11801-3:2017 provides guidance for designing physical infrastructure to support network communications in a manufacturing environment. That guidance is in the form of four MICE elements and three performance levels. The four elements of the MICE acronym include Mechanical, Ingress, Chemical/climatic, and Electromagnetic compatibility. The MICE standards define three performance levels and apply to cabling supporting EtherNet/IP, ProfiNET, EtherCAT, Modbus-TCP, and other industrial protocols.

In industrial settings, cabling must be able to withstand more severe environments compared to commercial settings. That’s where the MICE elements come in (Table 1):

- M for mechanical (shock, vibration, crush, impact, tensile force, flexing, etc.)

- I for ingress (such as water and dust in the forms of liquid and particulates)

- C for climatic/chemical (temperature, UV exposure, humidity, exposure to various chemicals and contaminants such as oil or gas, etc.)

- E for electromagnetic (surges, EMI/RFI interference, magnetic fields, transients, etc.)

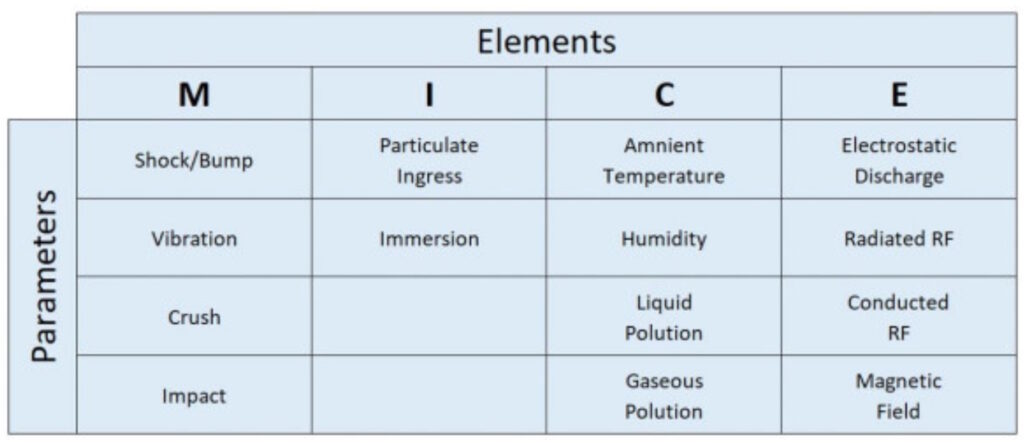

There are numerous sub-categories that comprise the MICE elements with detailed testing requirements including (Table 2):

- Mechanical considers shock & bump, peak acceleration, vibration (displacement amplitude from 2 to 3 Hz and acceleration amplitude from 9 to 500 Hz), tensile force, crush, impact, and bending, flexing, and torsional forces.

- Ingress considers particle ingress and immersion. This is the simplest category, and it requires ingress protection (IP) ratings of IP20 for level 1, IP65 for level 2, and IP67 for level 3.

- Climate/Chemical considers ambient temperature range, rate of temperature change, humidity, solar radiation, salt/sea water, oil, soap, detergent, conductive materials in solution, gaseous contamination, hydrogen sulfide, sulfur dioxide, sulfur trioxide, chlorine (wet & dry), hydrogen chloride, hydrogen fluoride, ammonia, oxides of nitrogen and ozone.

- Electromagnetic consider electrostatic discharge at 4 kV and 8 kV, radiated EMI, conducted EMI, electrical fast transient burst (EFT/B), surge, and magnetic fields at 50/60 Hz and at 60 to 20,000 Hz.

Depending on the location, improper implementation of the MICE elements can result in poor operating conditions and intermittent packet loss in industrial networks. For example, intermittent continuity can be caused by cable flexing or vibrations, corrosion due to various chemicals or moisture, and temperature changes causing contraction and expansion. The MICE standard is designed to address hard-to-find intermittent continuity problems before they arise.

In a MICE classification, a number (sometimes subscripted) appears after each of the four letters, like M3I1C2E3. The number represents the “severity” of exposure to the environmental factor and roughly corresponds to specific locations in a manufacturing facility. The higher the number, the more challenging the environment (Figure 1):

- For low severity, like a supervisor’s desk within a factory.

- For medium severity like light industrial environments on the factory floor.

- For high severity like heavy industrial settings and automation islands.

Examples of severity levels

Severity levels can vary widely; it’s not just all ones, twos, or threes. Consider the example above, M3I1C2E3. That indicates severe mechanical impacts with very little exposure to ingress, no immersion, medium exposure to chemical and climatic factors, and severe EMI exposure. It may describe a controller for a conveyor line sitting next to a large mixer using a variable frequency drive.

Looking at the temperature dimension in the C element:

- -10 to +60 °C, corresponds to C1 severity.

- -25 to +70 °C, corresponds to C2 severity.

- -40 to +70 °C, corresponds to C3 severity.

Not every stressor needs to meet the same level of severity within an element for a given application. For example, a robotic assembly stand on an automation island could have high flexing (M3), but little crushing stress (maybe, M1). As a result, products are usually designed to satisfy very specific application needs instead of being designed to meet all the requirements of a given severity level for each MICE element. That can make using the MICE classification system challenging since it must be applied on a case-by-case basis.

Summary

The MICE classification system is based on straightforward concepts of environmental elements and performance standards. It’s designed to help designers specify cabling for industrial networking environments. While the basic framework is relatively simple, there are numerous levels of details and testing requirements to ensure robust operation and no intermittent packet losses even in challenging industrial environments.

References

A Closer Look at Industrial Ethernet Cables, Fluke Networks

Industrial Cabling, Dintek

MICE Classifications Deciphered: What You Need to Know, Belden

MICE Environmental Classification, Leviton

MICE More difficult operating conditions as defined by ISO / IEC 11801-1 Chapter 6.2.2, Reichle & De-Massari AG

Leave a Reply

You must be logged in to post a comment.