Plating options are numerous and tend to fall into four categories: noble metals, passive metals, alloys, and dispersions. The first three categories are well established, while dispersions are just beginning to appear in response to the need for high-power connectivity in electric vehicle (EV) charging and similar applications.

This FAQ starts with a brief review of basic plating system concepts, then looks at the performance of noble metals, passive metals, and alloys, and closes with a glance at the potential benefits of dispersions.

Plating systems are often multilayer structures where the top layer can be a relatively thin plating. Passive metal surfaces like tin are often found in consumer products. Industrial, military, medical, and other high-performance applications usually turn to noble metals. Noble metals are often used as alloys. For example, pure gold is too soft for many applications, and gold alloyed with cobalt, nickel, or iron, called ‘hard gold,’ is used to provide more durability (Figure 1). Other noble metals like silver can also be used as alloys for improved hardness.

Figure 1. Plating systems consist of multiple layers of different materials (Image: Harting).

Noble metals

Gold is very conductive, even at low voltages. It has superior resistance to oxidation and corrosion compared to other options. It’s well-suited for use in environments with high humidity or frequent thermal cycling.

Silver performs well in high-power applications. Its lower cost compared with gold makes it a good choice for larger, high-current contacts.

Palladium has high electrical and thermal conductivity, and it’s resistant to corrosion. It’s harder than gold or silver, making it a good choice for applications that demand more durability.

Rhodium is harder than palladium, and it’s resistant to corrosion and acids. It’s well-suited for applications that need good wear resistance and high hardness.

Passive metals

Tin is non-toxic, making it suitable for some medical applications. It’s low-cost and suited applications that require a low number of mating cycles.

Nickel is very hard, durable, and corrosion-resistant. Its combination of durability and high electrical conductivity makes it suitable for high-use applications.

Copper has one of the highest electrical conductivities, but it needs a protective layer to prevent corrosion. It’s often used as a foundation for subsequent metal plating.

Metal alloys

White bronze is a non-magnetic alloy of copper, tin, and zinc and is more conductive than a nickel. It’s well-suited for many medical and RF connectors.

Palladium nickel alloy is corrosion-resistant and has low contact resistance. It has good solderability and can handle a high number of mating cycles. Palladium nickel plating is often flashed with gold.

Electroless nickel plating can be applied to conductive and non-conductive surfaces. Electroless nickel deposits are alloyed with up to 14% phosphorus. The higher the phosphorus content, the greater the corrosion resistance, but the hardness decreases.

Nickel phosphorus alloys have high wear and corrosion resistance. They have good solderability but have lower conductivity than other alloys.

Silver graphite dispersion

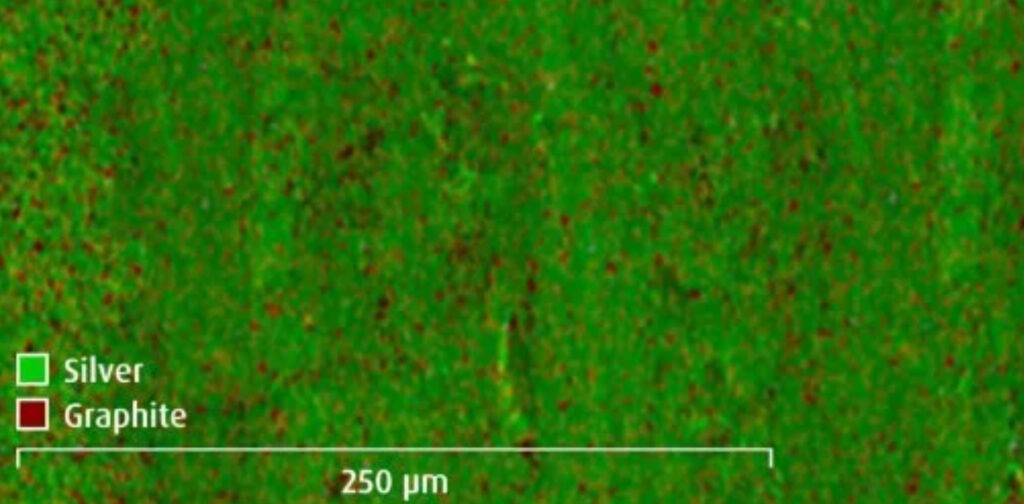

A silver-graphite dispersion has been developed for contacts in high-power applications like EV chargers. It combines the properties of fine and hard silver. The fine silver matrix provides high electrical conductivity, and the graphite increases abrasion resistance and supports high cycle lives. An even and random dispersion of the graphite particles is one key to the high durability (Figure 2).

Summary

A wide array of plating options is available that can support various levels of conductivity, environmental ruggedness, durability, and other application needs. The traditional choices between noble metals, passive metals, and various alloys are being extended with the development of graphite dispersion plating materials.

References

Contact plating material options for electronic connectors, Harting

Plating for Electronic Connector Pins and Contacts, Bead Electronics

Silver-graphite dispersion electrolyte contacts, Umicore

The Advantages of Gold Plating in Connectors, Positronic

Leave a Reply

You must be logged in to post a comment.