Liquid-cooled connectors are used in high-current, high-power industrial applications like electrochemical processes, welding, induction furnaces, electric arc furnaces, electrothermic processes, and electromagnets. This FAQ looks at various liquid-cooled cable and connector structures for carrying up to 60 kA.

Two keys to optimizing the performance of liquid-cooled connectors and cables are minimizing the resistance in the system and maximizing the heat transfer. The AC-to-DC resistance ratio is a particularly important consideration in power cable performance. The lower the ratio, the better the performance. The skin and proximity effects limit the AC resistance. Water-cooled conductors are often hollow or other structures designed to maximize thermal transfer and minimize DC resistance, but the structure can also increase AC resistance. The configuration of the conductors must be balanced to minimize the AC-to-DC resistance ratio and still allow adequate heat transfer.

General purpose cables

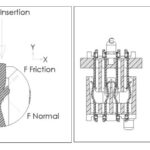

Many applications like welding and powering electromagnets require that the cables be flexible, and that can complicate the design. In one instance, the cables are formed using a copper spring core made with 0.50 to 1.5 mm copper wires covered with a copper braid formed of wires with a diameter of 0.20 and 0.31 mm, jacketed with neoprene allowing for low bending radii and simplifying handling in applications like welding (Figure 1). The cross-section of the square copper braid is determined by the amperage, and it has an internal hole for the passage of water. These cables use electrolytic copper, as defined in EN 13602.

Figure 1. These general-purpose water-cooled cable assemblies have a neoprene jacket for maximum flexibility (Image: Tesorax).

Electric arc furnace cables

For some high-power liquid-cooled applications, neoprene can’t be used, and more heat-resistant materials are needed. Water-cooled electric arc furnace cables are available with heavy-duty woven heat shields that provide protection from radiated furnace heat. In addition, the covering is designed for flexibility, ozone resistance, heat resistance, and abrasion resistance. The heat shield may be a loose-fitting sleeve or bonded to the outer hose depending on the application requirements.

The combination of the conductor design and water-cooled cable structure ensures a low AC-to-DC resistance ratio, due to its similarity to hollow tube conductors, for maximum current carrying capability. The combined core structure surrounds a core made with a rubber and nylon material that’s flexible, retains its shape, and ensures complete self-flushing water flow and even water distribution around the core for maximum cooling.

Stainless steel bands are used on the ends of the cable to ensure maximum sealing to the connector and eliminate the possibility of water leaks. The connector terminals are machined from electrolytic copper as defined in EN 13602 and plated with silver. The cable includes bumpers spaced 12 inches apart and made with abrasion-resistant rubber for maximum flexibility and reliability.

Cooling 50 kA

This family of cables is rated from 4.5 to 50 kA, requiring a cooling water flow of 2 to 23 gallons per minute (gpm) through the cable to maintain a maximum exit temperature of 65°C (150°F) for a 25’ cable (Figure 2). Vortex water flow action causes increased heat transfer and higher cooling efficiency. This results in increased flexibility, as well as additional water volume to conduct heat. The structure also insulates the wires from each other and allows water to come into direct contact with the copper wires.

Summary

Liquid-cooled cable assemblies are available using a variety of materials and with different structures to provide optimal performance in applications like welding, electromagnet powering, and arc furnaces. Cable structures have been developed that minimize the AC-to-DC resistance ratio to ensure maximum current carrying capacity and with optimal conductor geometries to ensure maximum heat transfer to the flowing water.

References

Electric Arc Furnace (EAF) Water Cooled Cables, Watteredge

Furnace and welding, Flex Cable

Special Cables and connexions of Copper, Tesorax

Leave a Reply

You must be logged in to post a comment.